Abrasive Material

High stability and efficiency

We provide stable surface roughness quality and highly efficient processing

by polishing film processing.

Wide range of applications

In addition to smoothening the surface,it is possible to add various functions such as reducing friction and improving releasability by achieving the desired roughness.

Features

Abrasive grain

・We handle a large number of silicon carbide, aluminum oxide, chromium oxide, diamond, etc.

Base material

・PET film, polyurethane foam, non-woven fabric, flocking, etc.

It can be used flexible depending on the application.

It can be used flexible depending on the application.

・With excellent high-precision finishing, automatic polishing by machine is also possible.

・The base material is flexible and works well for polishing curved surfaces.

※We also handle liquid abrasives (slurries).

Application

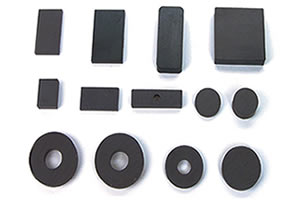

Surface finishing of developing rollers, photoreceptor, and transfer belts

→ Improved toner releasability, reduced frictional force

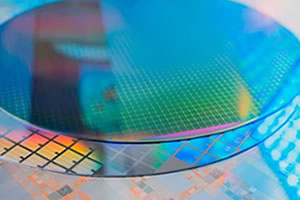

Edge trimming of semiconductor substrates φ8mm to φ450mm can be processed.

→ Remove sharp corners in the substrate process for inkjet heads

Prevents toner from sticking due to scratches and dents on the developing blade and nozzle plate

Cleaning card for cleaning the thermal head in the printer

Example of usage

Copier/ Printer

Inkjet printer

Car

Semiconductor