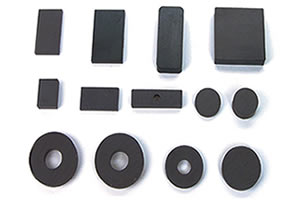

Zinc stearate bar

Solid lubricants that extend the life of OA equipment

Powder coating of photoconductors, printers’ photoreceptors and intermediate transfer belts by scraping the surface

This improves the durability of the applied material.

The headquarters material improves the mold release of toner from photoreceptors and belts, prevents adhesion of foreign matter,

Prevents the cleaning blade from twisting.

Features

Solid stability

・From the early stage to the late stage of machining, we have realized precision molding that guarantees a certain amount of machining.

Free-Determination Dimension Standard

・It is possible to change the product height and width from 5mm ~ 20mm.

Adjustment of surface shape

・Since the initial scraping amount is small, we can propose a surface shape with a proven track record of solving this problem.

Stable production

・Although it is a product that tends to generate air bubbles in the center of the solid shape, we provide products of stable quality by X-ray inspection equipment.To stabilize the product.

*This product is made by melting stearic acid and molding it into a bar shape. Therefore, Zinc stearate bar is used to coate at other product.Therefore, we can also provide brush roller with the for the product.

Application

Surface protection of photoreceptors, intermediate transfer belts, and secondary transfer rollers

Reduction of friction resistance, prevention of cleaning blade turning

Example of usage

Copiers and printers

Related Products

Brush roller