Flocked products

Various added values are added by electrostatic flocking.

Electrostatic flocking with various functions such as cleaning power, heat insulation, dew condensation prevention, design and luxury can be processed at a specified location with pinpoint accuracy.

Features

In the electrostatic flocking process, you can plant fibers in any location using static electricity.By planting fiber, various benefits can be given.

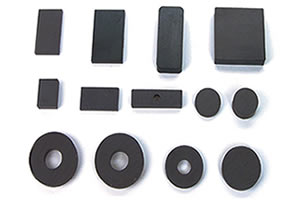

Molded flock

・Thermal properties (insulation/heat retention), slidability, and low wear can be imparted.

・It can also be used for decoration because the colors of the fibers used can be adjusted.

・Flocking is possible in designated areas of metal products and plastic products.

・Text and designs can be added by printing over the flock.

Flocked brush roller

・We can propose materials according to the required properties such as insulation and conductivity.

・Due to the unique high density of flocking, it is possible to clean the mating member evenly.

・Adjust the request progress according to the length of the brush.

Flocked sheet

・It has the same application as molded flocking, but since it is a sheet form product, it is easy to process and can be reduced in cost.

・It can be attached to the desired location by pasting with double-sided tape.

・Taking advantage of its high density, it can also be used as a sealing material for toner, etc.

Flocked brush roller

複写機・プリンタ

Flocked sheet

Application

・Prevents burns in high-temperature areas such as fixing parts (molded flocking)

・Prevention of condensation around the fixing part (molded flocking)

・Improvement of design and luxury (molding flocking)

・Cleaning the charging roller (flocked brush roller)

・Cleaning other parts (flocked brush roller)

・Seal for developing roller, edge of cleaning blade, and shutter

・Anti-reflection of optical components

Example of usage

Copier/Printer

Home appliances

Optical components

Related products

Brush seal