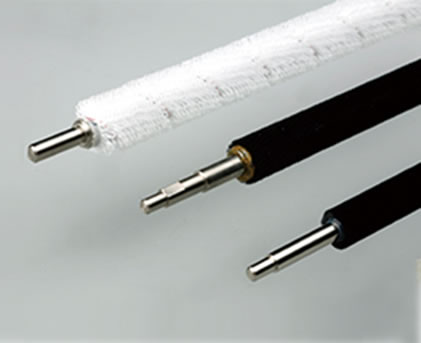

Brush roller

Super precision brush with custom pile spirally wrapped around the shaft

It is a toner cleaning brush mainly for copiers and printers.

It has been used for cleaning the photoreceptor, intermediate transfer,

secondary transfer, and fixing section of OA equipment.

It is possible to customize the fiber thickness, density, pile, etc.

according to the customer’s request.

Characteristics

Variety of materials

・In addition to materials such as nylon, PP, and PET, various selections of insulation and conductivity are possible.

Customized specifications

・It is possible to propose and manufacture high and low density, fiber thickness, pile length according to the application.

Precision processing

・High-precision outer diameter processing (shirring technology) suitable for office automation equipment and fine weaving accuracy are achieved.

Lot correspondence

・Because weaving (pile processing) is performed in a narrow width, it is possible to manufacture in large lots or less,

and we provide products with little waste.

Heat resistant

・There is also a heat-resistant brush with heat-resistant components such as brushes and adhesives.

(It can also be used for the fixing unit.)

Bar type brush

・We also handle rod-shaped bar brushes instead of roller-shaped ones.

You can consider depending on the space and price of the mounting location.

Application

・Precise cleaning of various belts and rollers in the photoreceptor, intermediate transfer, secondary transfer, and fixing sections

・Uniform application of solid lubricants, etc.

・Feeding and restraining paper transport

Example of usage

Office automation equipment

Air conditioner

Substrate cleaning equipment

Related products

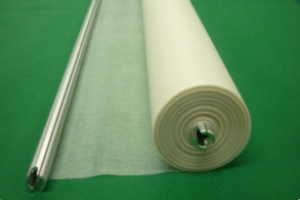

Brush seal

Web roller