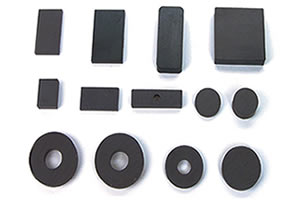

Resin bearing

Highly durable plastic ball bearings

Greaseless, highly durable plastic ball bearings

The advantages of resin bearing are lower cost, lighter and use fewer parts

Compared to metal bearing, the advantages of resin bearing are lower cost, lighter and use fewer parts.

Feature

Low price

・Significant price reduction is possible by replacing metal bearings.

High durability and long life

・By forming a highly durable skin layer on the resin surface, it has higher durability than general resin bearings and achieves a long life.

Skin layer on resin surface

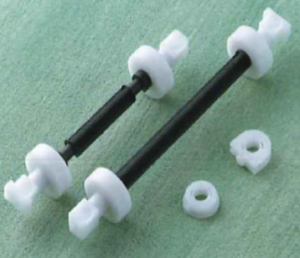

Reduction in the number of parts

・Taking advantage of the advantages of resin molding, it is possible to integrally mold parts including mounting brackets.

This reduces the number of parts and can be expected to reduce assembly.

Greaseless

・It can be used without grease due to the inherent self-lubricating property of the resin.Therefore, it is less likely to be affected by foreign matter or dust (such as paper dust).

Weight reduction

・Weight reduction (1/5) is possible compared to metal bearings.

Low torque

・Rotational torque is small, and power consumption can be expected to be reduced.

This leads to cost reduction, including peripheral components such as motors.

Conductive type

・There is a lineup of conductive types that use conductive resin for areas that require conductivity.

Application

・Various bearings・・・Development screws, transport rollers, etc.

・Copier ADF (automatic paper feeder) and feeder pulley

・Various bearings for banknote transport in financial equipment

・Car steering column

・Drone Rotating Part Bearing

Example of Usage

Copier/Printer

Car

Financial equipment

Optical equipment

Related products

Multifunctional toner transport resin screw

Rubber roller

Sponge roller